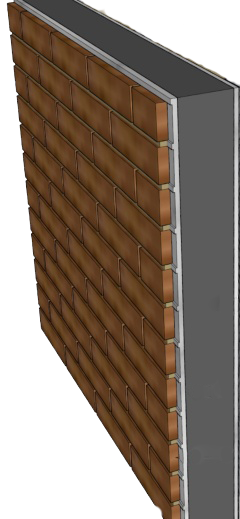

Our SIP / Composite Panels (CSIP) come with or without our Brick Slip Tracking System

Cement Fibre Boards A1 approved Composite Fire Rated wall systems for all Buildings

We manufacture an extensive range of panels to cover the

most popular sizes namely 70mm, 95mm, 145mm, 170mm & 220mm by

1220 x 2440 - 1200 x 2900 & 1220 x 600 or Bespoke

Our Standard Size is 70mm

Brictec's Fibre Cement SIP Panels are Fire proof, Toxin Free

and harmless, Sound insulation, Moisture resistant, Heat

resistant, Impact resistant, Moth proof, Nailable, Sawable,

Drillable

Our cement board is a combination of cement and reinforcing

fibres formed into sheets.

It is Fire Retardant, Water Proof and Insect Proof, and is not

prone to warping or cracking, thanks to the cellulose fibres

which boosts it dimensional stability.

We currently supply various companies across the construction

industry who have benefited from its excellent fire resistance

/as well as being lightweight and water resistant is ideal for

Extensions and Garden rooms

|

|

We manufacture energy efficient Cement Fibre Skin Insulated panels (CSIPS). Our CSIPS are manufactured with a

expanded polystyrene insulating foam core of 1 to 3 pound

density,

that is sandwiched between two 6mm/9mm/12mm/15mm/18mm/22mm” thick cement

fibre skins. Buildings constructed with CSIPs are more durable

and will require less maintenance than buildings with OSB SIPs

panels.

Fibre-Cement Board SIPs will not rot or corrode and have a

higher fire resistance than OSB SIPs.

Cement Fibre boards will not support black mould growth and

have a high resistance to moisture absorption.

CSIP panels emit no know toxins and are classified as a “Green

Building Material.” With the use of our CSIPS panels, drywall

can be eliminated which further reduces the time and cost of

construction. our panels are not for load bearing. Fibre

cement SIP panels are made with a mix of ingredients, namely

Portland cement, cellulose fibres, fly ash, and water1. This makes for a highly

flexible and strong material for Construction Panels,

unlike regular concrete, which is rather rigid and breakable1.

The panels are available in 70mm as standard or Bespoke and are fireproof,

waterproof, and insect-proof.

They are not prone to warping or cracking, thanks to the

cellulose fibers which boost their dimensional stability.

The exterior surface of CSIPs can be painted or coated with a

synthetic stucco finish, lap siding and a host of other

suitable exterior finishes.

Our

CSIPS used to construct load-bearing walls up to three

stories, roof panels and floor panels. Brictec's CSIPs are

manufactured in our facility with state of the art equipment,

to produce one of the highest quality CSIPs available on the

market. Brictec's CSIPS are extremely strong, durable, energy

efficient and cost effective.

Our

SIPs or Structurally Insulated Panels come as 2400 x 1200 or

1200 x 1200 or 1200 x 600 as standard or we Manufacture to whatever size you

require at no extra cost, we use A1 Fire Proof

Fibre Cement (Portland Cement) Panels with a BBA approved

insulating foam core if required. This gives a high strength to weight

ratio allowing large sections of your building to be fitted at

once, speeding up the time required on site.

The result is a building system that is extremely strong,

energy efficient Fire Proof and cost effective. Building with

our CSIPs will

save you time, money and labour.

SIP Panels are used increasingly for the inner skin of office

developments or as an insulated structure for cladding

systems. Our SIP's can come with or without our Brick Slip

Cladding System. The insulating properties of the panels offer

a warm environment for the staff whilst substantially reducing

heating costs to the company.

Using our CSIP Brick Slip Tracker Panels with Render

Our Fibre Cement product ranges are rated as having some of the best

structural properties in the market and rate high on crucial parameters

– e.g. “A1” rated to British and European Standards on Fire resistance,

as well as high scoring on water resistance, impact strength, sound

proofing, Thermal insulation and insect & fungus resistance. As well as

being one of the best-rated boards for dry walls and ceilings, our

boards are also certified to clean room standards.

Product update – NO Magnesium Oxide (MgO) in any of our products

Further to recent press releases and news reports.

Many authorities, inclusive of NHBC, have issued directives in

March 2020 stating that they will no longer accept MgO building boards

on buildings. This ban applies to any buildings where the foundations

are begun on or after 30th Aril 2020 under its insurance warranty. These

boards have shown that they condense humidity which can lead to severe

problems resulting in a complete ban in Denmark in 2015. Premier

Guarantee / LABC Warranty will also no longer accept the use of these in

any of its structural warranty schemes.

Our customers will be please to know that none of our boards have any

MgO content.

Garden Office Commercial or Residential

Brictec Systems, Clad, Brick Slip, Repair, Insulate and Improve any Building

SIP Panels render Boards and Brick Slip Backer Boards, to Insulate and Improve any Building

|

|

|

| Next Day Delivery in Stock - ( DISCOUNT on QUANTITY ) | ||

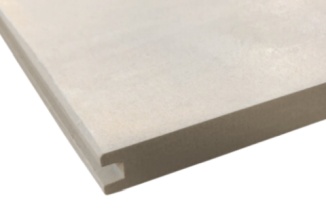

| EXTERIOR -

INTERIOR FIBRE CEMENT BOARDS 2400 x 1200 (8x4) 12mm £34 -

9mm £28 - 6mm £22 A1 Non combustible / BBA Certified Fibre Cement Building Board. And Tongued and Grooved Flooring 15mm- 18mm- 22mm Available Category A board to BS EN 12467:2012+A2 2018 |

||

|

|

|

|

At Brictec, we are a specialist manufacturer and complete supplier of External/Internal Wall Insulation (EWI) Certified Fibre Cement Building Board to the UK construction industry. We ensure the supply of fibre cement building boards, façades and insulation which is also known as our Eco Board and Bonus range of products. Brictec works closely with architects, specifiers and contractors to ensure the correct fire protection products are used at all times and to the correct specification required by the client. From planning to completion, we expertly guide our clients during their fire, blast, impact, sound or moisture protection project, ensuring a fit-for-purpose and accredited solution is both specified and delivered. All of our insulation and fibre cement products are A1 Non Combustible following through testing in order to be EN 13501-1, as classified by the BRE. |

||

|

|

|

|

Our Fibre Cement natural cement boards are

produced using only cellulose fibres and with autoclave

method are presented on the market to be used as interior

and exterior siding material, in plain board form and with

different surface appearances. Manufactured entirely with natural materials, environment, nature and human friendly. It is very resistant to atmospheric conditions; it is not affected by ultraviolet rays. It does not decay, is long lasting and does not require special care. Can be easily worked with suitable tools and is easy to install. Does not include any asbestos or materials harmful to human health. Is a non-combustible construction material of A1 class according to EN13501-1 As it removes fine plaster work in construction, it saves time and labour. It has good sound and thermal insulation properties. It is resistant to impact and shock. Is resistant to freezing and can be safely used in the coldest of climates. In the event of a possible fire, it does not emit gasses harmful to humans or the environment. It is resistant to impact and shock. It is not affected by water and can be safely used in humid conditions. Can be repeatedly painted by water based interior and exterior paint. Can be used as a sandwich or press panel material for different applications. |

|